Aero Gama srl is a company that operates in the field of precision mechanics and general mechanics.

The company, qualified ISO EN 9100 and ISO 9001, mainly operates in the aerospace sector and boasts as customers the major players at national level.

It has been structured over the years to guarantee precision, punctuality and competitiveness on the market, putting in place numerous investments aimed at increasing and varying more and more the products offered.

The company operates thanks to 26 resources including 3 engineers and mostly qualified personnel, is located in Orta di Atella (CE) 5km from the A1 motorway, on an area of about 6000 square meters, boasts as capabilities:

-for machining (milling and turning) 18 machining centers of various types, with technology up to 6 controlled axes and strokes up to 4 meters, as well as traditional M.U., grinding, sawing machines and more;

-an area equipped for light and heavy carpentry with mig, mag, tig, continuous wire welding departments;

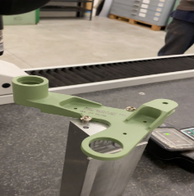

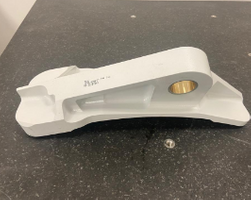

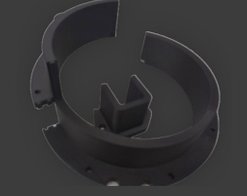

-3D printing in ABS, PLA, carbon fiber, kevlar, glass fibers and more;

- a design and cad/cam area with Catia V5 software and Vero-Solutions;

-a metrology room in a controlled environment according to ISO 9100 standards equipped with 5ax MMC;

Area dedicated to research and development;

Our production is diversified into:

aeronautical components :

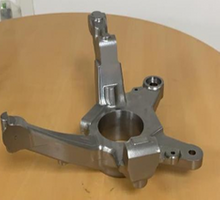

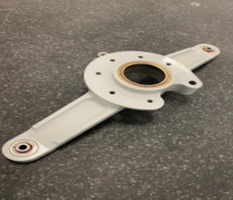

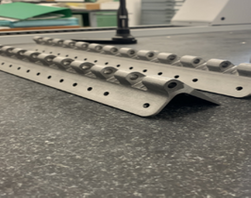

We produce precision mechanical parts with technology up to 6 controlled axes and length up to 4000mm, we are also qualified for the realization of small assemblies through the installation processes of rivets, bushings and bearings, cyanide and chewing.

We have participated in the production on multiple aeronautical programs, including the surround cargo door and the floor of the B787, passenger, emergency and cargo doors of the ATR 42/72, floor of the A380, ATR fedex version, large cargo door ATR, A320, B767, EFA, C27J and many others.

The materials processed are those typically used in the aeronautical sector: aluminum alloys, steel alloys, titanium, inconel.

Aeronautical equipment and machinery :

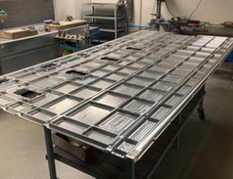

Design and construction of equipment, test benches circuits and oil-hydraulic, pneumatic and electrical components for the G.S.E. (ground support equipement)

Equipment for shoring and lifting aircraft and parts thereof.

Equipment for the disassembly and assembly of aeronautical components.

Design and construction of machinery according to customer needs

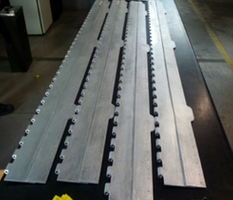

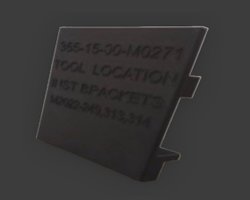

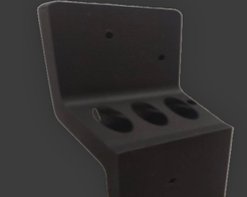

Control gauges, forming and trimming templates for composite parts, fixtures for measuring parts, drilling masks.

Assembly stops and automated production areas

Main Customers

Main Machines

The vast machine park includes technologically advanced machining centers for the processing of both heavy alloys and light alloys

Aeronautical Components

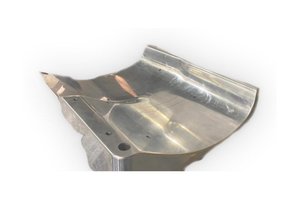

Male composite lamination tool (41E), for the realization of carbon fiber part "Spring Fairing", ATR program

designed in accordance with the requirements and guidelines described in the Leonardo M123 manual section 2.4 (AdN)

Female composite lamination tool (41E), for the realization of carbon fiber part "rudder panel", ATR program

designed in accordance with the requirements and guidelines described in the Leonardo M123 manual section 2.4 (AdN).

Female composite lamination tool (41E), for the realization of carbon fiber part "LH and RH Cover", ATR program

designed in accordance with the requirements and guidelines described in the Leonardo M123 manual section 2.4 (AdN).